Le Groupe

Nos 170 personal printers imaginent et conçoivent chaque jour les innovations de demain. Découvrez notre histoire, nos valeurs, notre organisation.

Notre vision

VISIONNAIRES

DANS L’ESPRIT

À la mesure des révolutions technologiques et techniques, le secteur de l’imprimerie n’a cessé d’évoluer.

Prenant la mesure de ces profonds changements, nous nous réinventons sans cesse pour garantir à chacun de nos clients une réponse adaptée à la réalisation de ses projets.

Au cœur : l’écoute et

l’accompagnement

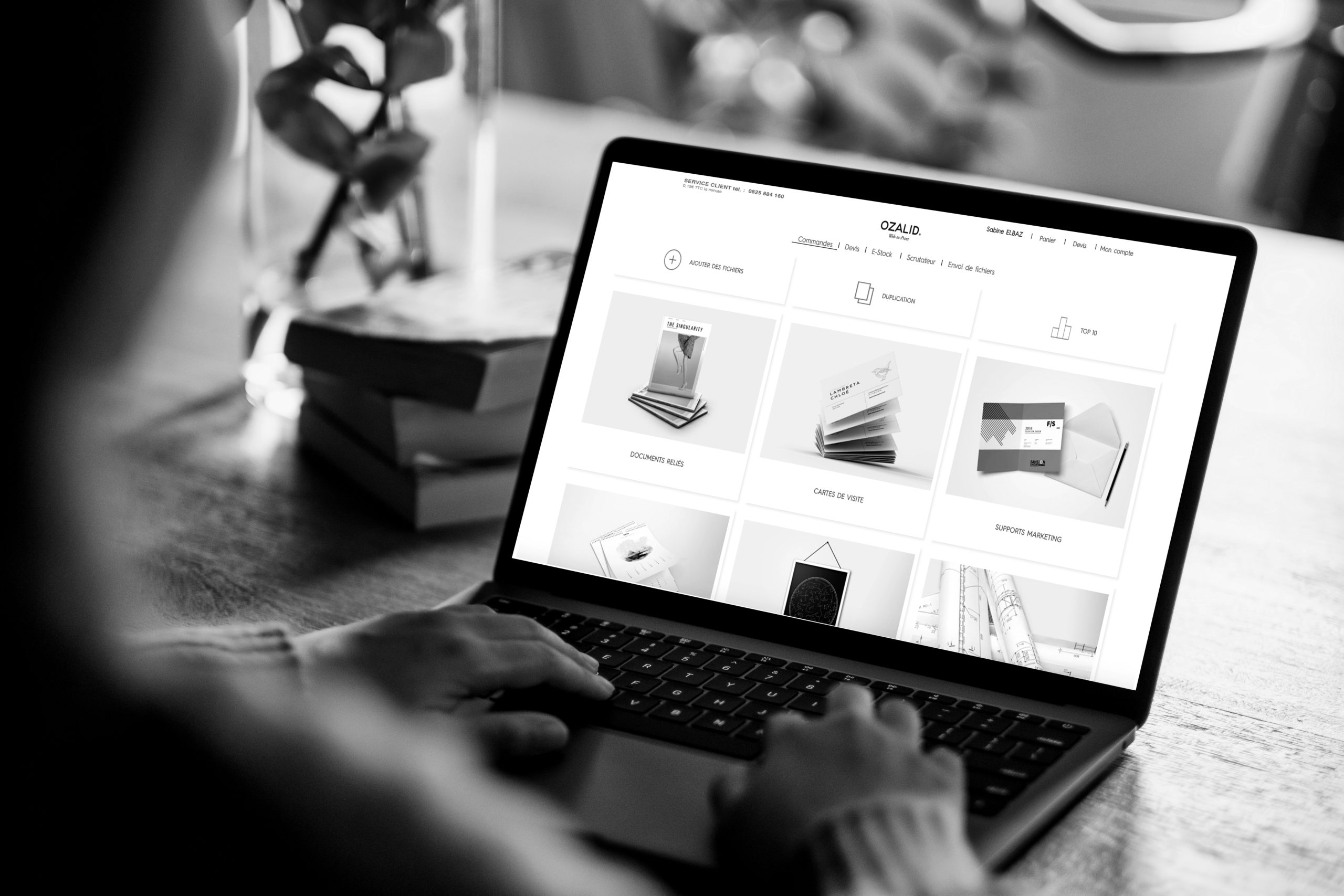

Nous nous plaçons aux côtés de nos clients pour leur apporter un accompagnement centralisé.

Ainsi, ils sont à même de se concentrer pleinement sur leur activité tout en s’assurant d’une prise en main sérieuse et experte de leurs problématiques d’impression.

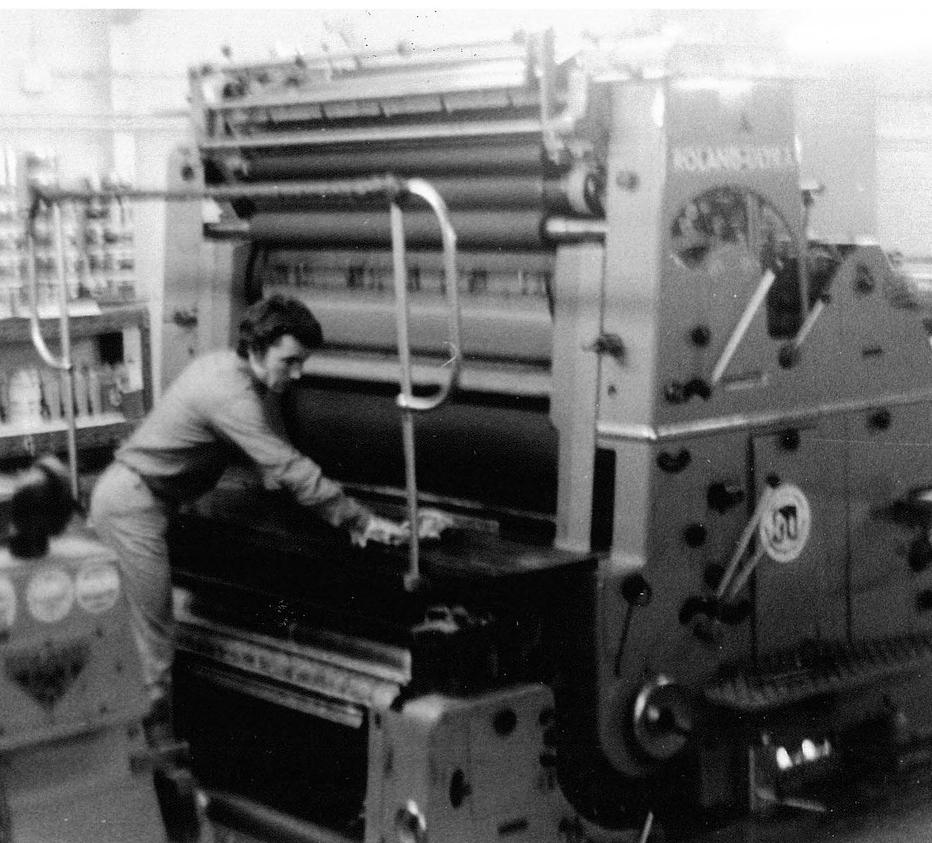

L’expertise en héritage

Précurseurs dans l’âme, experts dans l’exécution, nous maîtrisons l’ensemble de la chaîne graphique.

Guidés par notre esprit pionnier, nous sommes en mesure de concevoir des solutions d’impression clés en main et innovantes pour répondre de façon ciblée à chaque problématique.

La créativité :

Notre meilleur atout

Parce que nos clients sont multiples, parce que leurs besoins sont uniques, les offres et compétences que nous déployons sont plurielles.

Jour après jour, nous mettons notre créativité au service de la conception de solutions sur mesure et personnalisées, pour donner à nos clients une plus grande force d’expression.

C’est parce que nous mettons au cœur l’écoute, la réactivité et l’inventivité que nous nouons quotidiennement une relation de confiance avec chacun de nos interlocuteurs, nos collaborateurs, nos clients autant que nos partenaires.

Nos chiffres clés

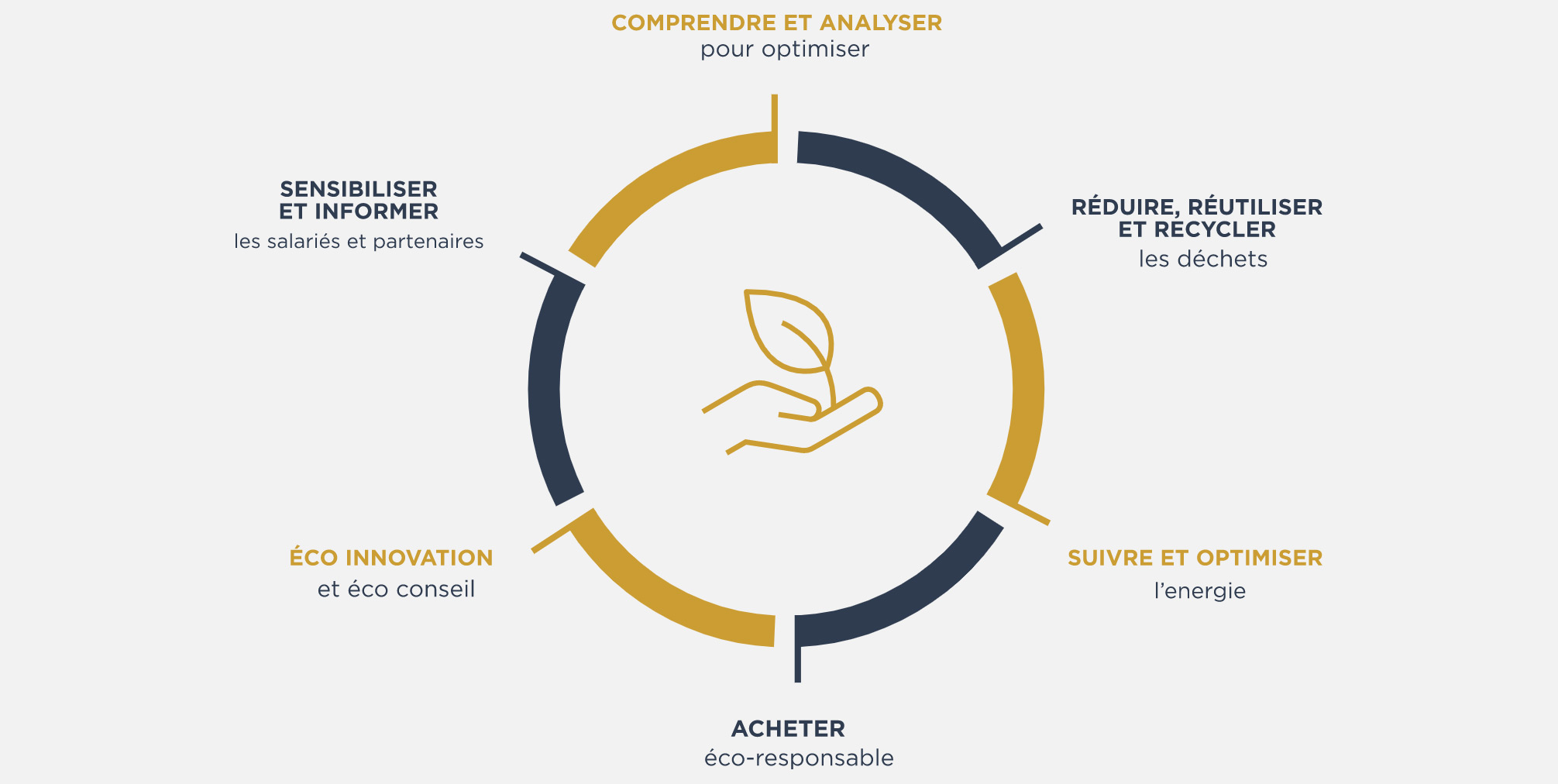

Un véritable engagement neutralité carbone

Une politique RSE active

Très tôt, nous avons voulu adopter une démarche durable et responsable. Nous avons été le 1er imprimeur numérique à obtenir la certification ISO 9001 en 1995, avant de recevoir le label Imprim’Vert dès 2007. Aujourd’hui, nous poursuivons cette recherche d’une empreinte raisonnée, effectuant notamment des bilans carbones au sein de nos unités de production.

Les papiers sur lesquels nous imprimons sont issus de forêts gérées durablement et bénéficient des labels FSC ou PEFC. Nos chutes de papier sont systématiquement pesées et collectées pour recyclage et valorisation par VEOLIA. Les déchets d’encres et toners sont collectés par la société CONIBI, puis triés pour valorisation dans les filières de métaux et plastiques.

Enfin notre modèle qui consiste à privilégier la production locale et les circuits courts (clients à moins de 50 km d’une de nos unités de production en Ile-de-France) nous permet de limiter l’impact environnemental des livraisons.

Parallèlement aux actions que nous menons au quotidien pour réduire notre empreinte environnementale, nous avons choisi de nous inscrire durablement dans les projets de captation carbone par la reforestation en France.